Transfemoral Prosthesis

July - Dec 2018

Millions of amputees require above-knee prostheses. Many non-government organizations like Ratna Nidhi Charitable Trust fabricate and supply them to marginalized patients. They needed to improve the fitment using patient-customized sockets, and yet reduce the overall lead time. The project was carried out at the Biomedical Engineering Technology Innovation Center, IIT Bombay and supported by Google. It also involved IIT Madras (for knee joint) and MGM Hospital (for gait study).

Team

Lalit Amrutsagar (Lead Researcher), Arvind Bhallamudi (Intern), Viren Dhumal (Intern), Dr. Trimbak Kawdikar (Physiotherapist), Dr. Rupesh Ghyar (Guide)

Role

Caried out measurement design, generation of stump models using field data, comparison and validation of the developed parametric model, and supported in fabrication and assembly.

Focus Areas

Mechanical Engineering

Manufacturing

Industrial Design

3D Scanning

Research and Analysis

Problem Scenario

India has a large number of trans-femoral (above-knee) amputees who need high-quality yet affordable prostheses to return to near-normal life. Current low-cost prostheses such as ‘Jaipur Leg’ use a plaster replica of the residual limb of patients to fabricate a matching socket. Stump replication is a cumbersome process that requires skilled technicians, challenges the dignity of patients and often requires rework.

Img.1-4 Conventional prosthesis process: 1) Plaster-of-Paris to create a negative of the stump, 2) using that to create a positive replica of the stump, 3) sanding and manual work to finish, 4) using heated PVC pipes to form the socket.

Research on Conventional Prostheses

Study on conventional prosthesis pointed to the need for a patient-customized above-knee prosthesis with better conformance and shorter fabrication time (compared to conventional Jaipur Leg). Design goals and requirements focused on four areas:

-

Streamlined and reduced skill and effort to measure patient stumps.

-

Conforming and better fitment of designed socket with patient stump.

-

Throughput and efficient fabrication process to increase the production.

-

Affordable and suitable for large scale deployment and use by NGOs.

_edited.jpg)

Fig.1 Loadbearing regions in leg anatomy.

Fig.2 Identifying the same regions in the replica.

Img.5 Existing prosthesis with single-axis knee joint and Jaipur foot.

Measurement Design

21 dimensions identified in discussions with clinicians and technicians, to semi-automatically generate a parametric stump model for patients. We also tried generating the stump model by 3D scanning but this method had limitations in accuracy as well as logistics. To facilitate proper measurements and their recording by field workers, an intuitive and bilingual chart was designed. These measurements will be used to parametrically generate a CAD model of the patient’s stump, which can be used to fabricate a socket.

Img.6,7 Field work and measurements at a remote camp in Satara, India.

Fig.3 Bilingual measurement sheet designed for clinicians and technicians to use.

Parametric Model Comparison

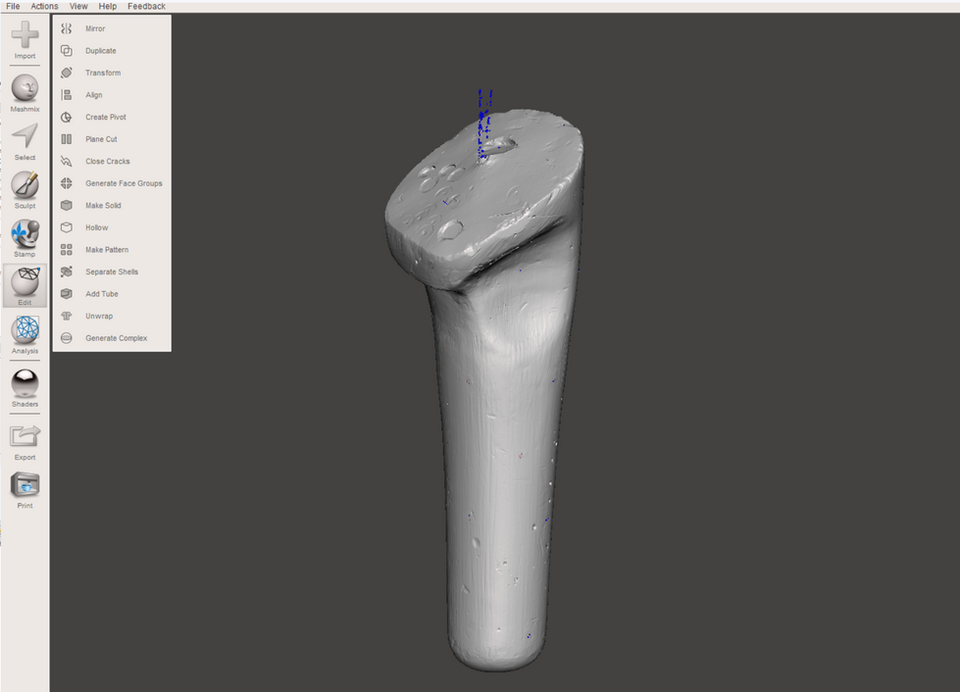

Using field data from measurement camps, we generated parametric CAD stumps of multiple patients, followed by fixing and modifying the form to improve conformity. To test the conformity, the parametric CAD stumps were compared to conventional plaster stumps by 3D scanning the plaster stumps using Steinbichler Comet L3D. The distance between cloud points of these two meshes was analysed using CloudCompare and were found to have an accuracy of 90% up to 8 mm in deviation.

Fig.4 Parametric CAD model designed from measurements.

Fig.5 3D scanned conventional plaster stump.

Fig.6 Cloud point comparison to measure deviation in parametric models.

Manufacturing and Assembly

The parametric model of the patient stumps were exported for manufacturing using CNC machining. The stumps were then coated before fabricating corresponding sockets using conventional socket molding procedure, followed by the rest of the prosthesis.

Img.8 CNC machining of stump from parametric model.

Img.9 Coating the stump models before socket forming.

Img.10 Final prosthesis assembled with the parametrically-designed socket and with a more functional polycentric-knee.

Testing and Outcomes

The gait of different prostheses was tested at Center for Human Movement Science, MGM Hospital, Mumbai. Patients in remote areas do not need to travel to cities since field workers can take their stump measurements and send them to the fabrication centre. The prostheses can be fabricated and delivered to the patients. The patient-friendly approach leverages design and technology to improve the overall functionality, productivity and affordability, enabling scale-up.

Img.11 Gait study with the patient at MGM Hospital, Mumbai.

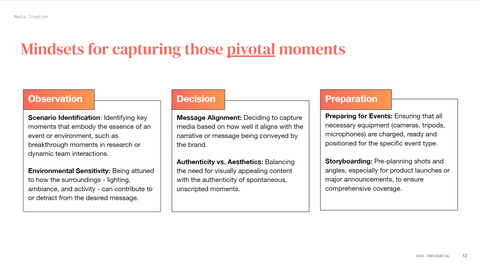

Multimedia and Communications Plan

Balancing creative writing with technical information was done in parallel with the assisting the design team with layouts, visual graphics, imagery and interactions. The communications strategy and website were refined, tested and launched in June 2024.

.png)