Mycotype

2023 - PRESENT, RHODE ISLAND SCHOOL OF DESIGN

As the world grapples with escalating crises of climate and environmental degradation, this work explores the synergistic potential of design and biology. Working with fungi, the it proposes an accessible and versatile biomaterial protocol. It utilizes local waste streams to grow functional mycelium-bound structures, materials, prototypes and products. An experimental, small scale, carbon-negative system is modeled after monotubs, grow-tents and bio-printing methods. The materials’ performance and applications are evaluated through mechanical testing, surveys and workshops.

Advisors

Tom Weis (Thesis Chair, RISD ID Department), Dr. Andreas Mershin (Advisor, MIT Center of Bits and Atoms), Jennifer Bissonette (Advisor, RISD Nature Lab)

Role

In this year-long Master's thesis, I carried out research, experiments, material development, design and fabrication of materials and products.

Focus Areas

Circular Design

Carbon Capture

Biomaterial Design

Industrial Design

Material Characterization

Prototyping Workshops

Current Scenario

The world generates 2.01 billion tons of municipal solid waste annually, with at least one-third of that not managed in an environmentally safe manner (World Bank). By 2050, scientists predict more plastic will be in the ocean than fish, including micro-plastics that threaten marine life and contaminate human food and water sources. E-waste and smartphones, largely composed of plastic, are among the fastest-growing waste streams. Food waste is another significant issue, with a third of food produced globally per year—1.3 billion tons—going to waste. The construction sector, reliant on concrete and metals, also contributes heavily to resource extraction and pollution.

There is a pressing need for innovative solutions that can divert and transform inevitable waste streams while remaining flexible with inputs and providing value to the ecology and the community.

Img.1 Rhode Island Resource Recovery Center (RIRRC), the state's central landfill at full capacity in 2025.

Fig.1 A mind map about materials and design for a circular economy.

Fungi and Circularity

Nature has long provided elegant solutions to resource management and waste disposal, presenting valuable lessons for addressing the issues of the material domain identified in the previous section. A natural process that could solve our waste problems is that of mycelium, the underground network of fungi. Mycelium plays a critical role in decomposition, breaking down complex organic materials into simpler compounds used by plants and other organisms. It is made of threadlike structures called hyphae, and holds great potential for transforming waste into useful materials.

Img.2 (ID)

Img.3 Turkey Tail mushroom (Coriolus versicolor)

Img.4 Oyster mycelium growing on coffee ground waste.

Fig.2 Ideation sketches and logic diagrams for the products and processes possible using fungi.

Initial Experiments

For most scientists, the preferred research mode is one with fundamental questions, systematic experimentation, and repeatable results. The scientific revolution of discovering fundamental elements and processes found in biology, chemistry, and physics has been instrumental in creating a foundation of knowledge in universal systems. It has completely formed the society we live in today.

On the other hand, many designers focus on applying scientific, technological, and cultural data to creative and functional ideas and interventions. In working with biological materials such as mycelium, we need to incorporate both scientific and design research methods and adopt an interdisciplinary approach to biomaterials. following protocols, documenting results and iterating.

Img.5-10 Conventional mycelium molding process: sterilization and setup, inoculation, colonization, extraction, drying.

Workshop.1 Mycelium molding process co-taught in a course with Calgary Haines Trautman at RISD.

Material Design

Replacing foam with mycelium-based composites at RISD required addressing challenges in traditional mycelium molding processes. By understanding pain points, substrate selection, mold design, preparation, and growth conditions were specifically improved to establish a new material system that overcomes limitations. This resulted in a formulation using locally sourced saw dust and coffee grounds with mycelium from the Ganoderma lucidum mushroom.

The tests and workshops with students from different departments proved that pre-grown mycelium materials could offer an alternate approach to growing mycelium from scratch, which can otherwise be time-consuming, expensive and challenging. The benefit of myco-materials is their versatility to conform and break down, their low-fidelity nature that enables creativity and sustainability, and their inherent qualities of waste transformation and biological circularity.

Despite the limitations, such as in sanding, handling screws and inserts, and certain processes like laser cutting being inappropriate due to the material’s charring nature, with denser and more rigid mycelium materials as the next step, compressed composites or ‘myco-sheets’ could hold promise to address some of these concerns.

Img.11 Myco-block materials, lightweight and insulating.

Img.12 Myco-sheet materials, compressed for higher strength.

Img.13-16 Operations on myco-materials: sanding, machine drilling, bandsaw cutting, painting, laser cutting.

Characterization

Mechanical testing evaluates mycelium materials’ specifications for safety and resistence to failure in various contexts, ensuring the final product meets the required performance criteria. By understanding these, we can determine the suitability of mycelium materials for applications in consumer goods, construction, packaging, textiles, or others. Three key mechanical properties selected for characterizing mycelium; compressive strength, water absorption, and density.

There is an equal focus on performative, affective, interpretive, and sensory aspects. From a design perspective, the experiential scope will help better understand perception, behaviors, emotions and usability of the material. After initial testing, a workshop survey at RISD Grad Exchange in April 2023 was organized to share this project and gain valuable insights through feedback from students.

The survey compared two versions of mycelium samples: uncompressed (myco-sheets) and compressed (myco-sheets). It drew participation from 40 graduate students representing various departments and providing diverse perspectives. The participants’ responses indicated a significant interest among students in further exploring the materials. 62% of the participants expressed their interest for material testing and prototyping and requested samples of custom composites. This enthusiastic response is a testament to the growing demand and fascination surrounding mycelium within the design field.

Img.14,15 Survey workshop conducted during the RISD Grad Exchange event in 2023.

Fig.3,4 Mechanical characterization and experiential characterization of two types of mycelium-waste composites.

Process Development

Fig.5 Process map describing steps and variables in growing mycelium.

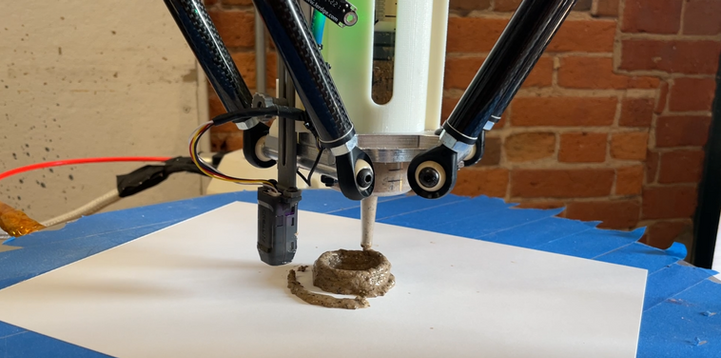

Img.16-19 Different approaches to growing mycelium: digital mono-tubs with environmental conditions sensed and displayed, semi-automated Martha tents with a air exchanger and humidifier, and experimental 3D bioprinting.

Fig.6 Process map with inputs and outputs of a particular case using coffee grounds and blue oyster fungi.

Product Applications

Four types of products are conceptualized and grown using the conceived formulations and molding processes: 1) breathable planter, 2) modular furniture set, 3) lampshade with motion detection, and 4) furniture repair with mycelium paste. These concepts add to the range of possibilities along with pre-grown myco-materials, allowing more complex forms using CAD, 3D printed molds and custom processes to improve their structural integrity, durability, and surface finish.

Img.20-24 Product prototypes: biodegradable planter, modular furniture, mycelium lamp, mycelium furniture repair.

Multimedia and Communications Plan

Balancing creative writing with technical information was done in parallel with the assisting the design team with layouts, visual graphics, imagery and interactions. The communications strategy and website were refined, tested and launched in June 2024.

Conclusion

The experiments, objects and processes from this study were shared with the design community through two exhibitions, the book 'Fungi in Flux' and a series of talks and workshops for students, educators and professionals who are looking toward sustainable and circular materials in their work.

Img.25,26 Exhibited at the Rhode Island Convention Center.